Stainless steel chains

Stainless steel chain is widely used in food processing, pharmaceutical, chemical production, rubber processing, non-ferrous metal smelting, electronic equipment, environmental protection equipment and heat treatment equipment.

Stainless steel conveyor chains

Please contact us for details.

Mail:[email protected]

Manufacturer supplier exporter of drive chains.

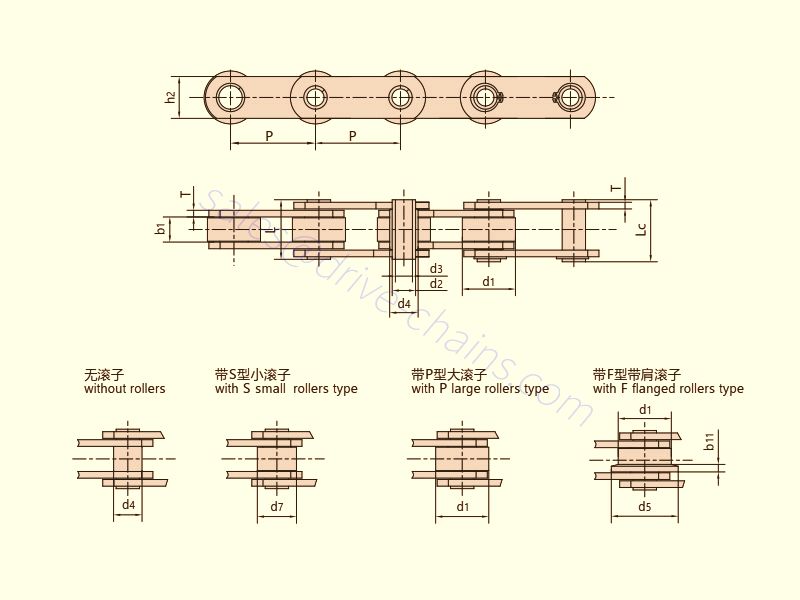

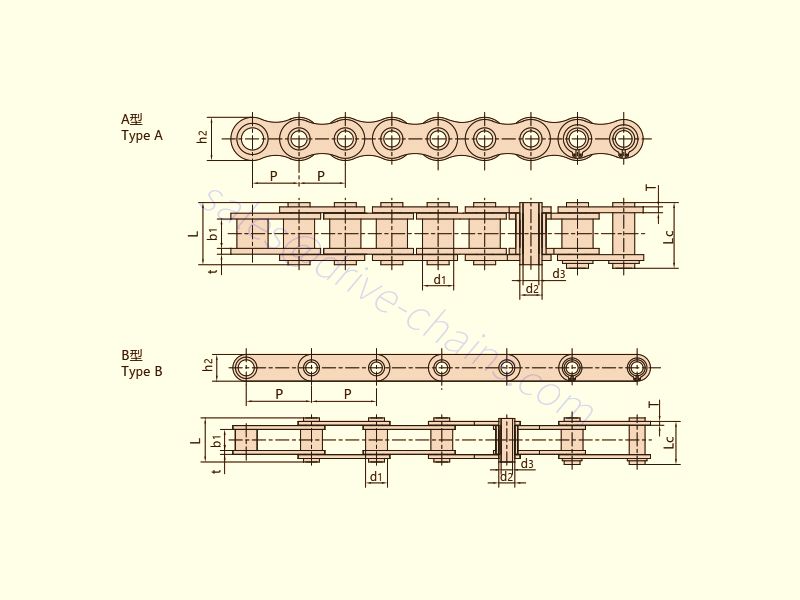

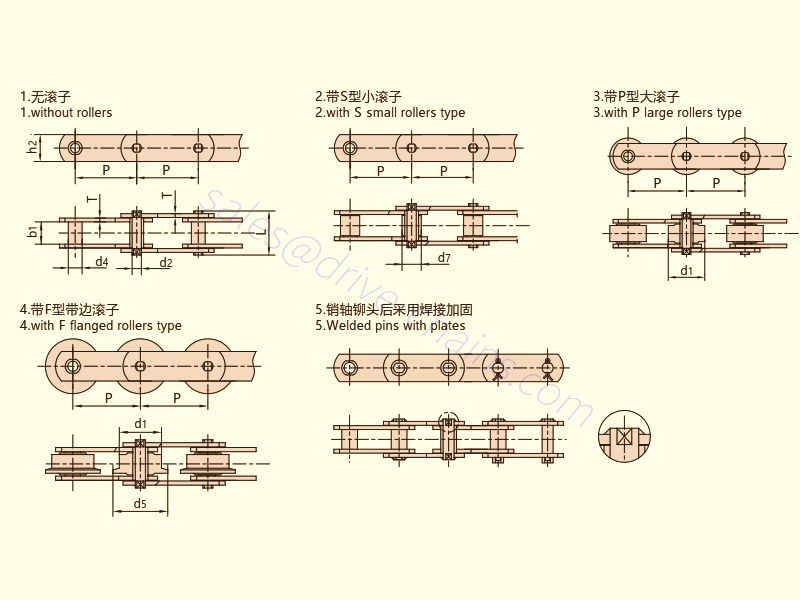

● Stainless steel conveying chain mainly includes stainless steel hollow pin chain, stainless steel conveying chain (M series), stainless steel hollow pin chain (MC series), stainless steel sharp tooth chain, and other products whose structure and size are the same as those of similar carbon steel chains;

● Using high-quality austenitic and martensitic stainless steel materials, advanced processing technology, and efficient process equipment, the products have the characteristics of corrosion resistance, high and low-temperature resistance, cleanness, etc. There are two kinds of products with tensile strength indexes for users to choose from.

● Products are widely used in metallurgy, food processing, high-temperature or low-temperature equipment manufacturing, sewage treatment, and other industries.

Factors to be considered in the high and low-temperature environments are as follows:

I. Low-temperature environmental factors<br> Cold brittleness of materials, that is, the impact strength of materials decreases at low temperature, generally depends on the chemical composition of materials, and stainless steel chains should not be used below the specified temperature.

The minimum working temperature of stainless steel chain

| Chain material | Minimum operating temperature/℃ |

| Martensite type stainless steel | -70 |

| Austenitic stainless steel | -100 |

II. High-temperature environmental factors

The strength of the chain decreases with the increase in temperature. The minimum ultimate tensile strength of stainless steel chain in a high-temperature environment above 400℃ is the minimum ultimate tensile strength /Kt in general applicable environment temperature (-20℃ ~ 400℃), and the Kt value is shown in the following table:

Temperature coefficient of stainless steel chain

| Ambient temperature | Temperature coefficient Kt |

| Below 400℃ | 1.0 |

| 400℃~500℃ | 1.2 |

| 500℃~600℃ | 1.5 |

| 600℃~700℃ | 1.8 |

| 700℃以上 | Not available |

Applications:

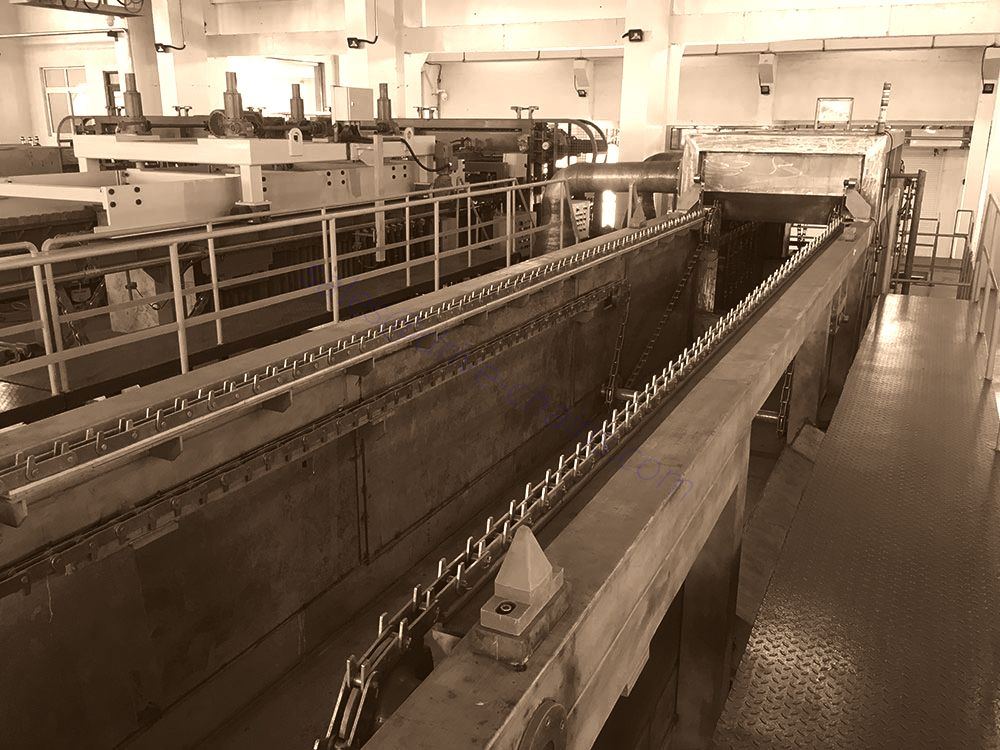

(1) Environmental Protection Industry

Chains used in the environmental protection equipment industry are widely used in water treatment equipment and various regeneration and recovery equipment, including sewage treatment facilities, scrapped automobile dismantling production lines, domestic garbage comprehensive utilization environmental protection treatment lines, garbage incineration power plants, etc.

Features:

According to industry characteristics, the chain for environmental protection equipment is made of various high-quality alloy steel and unique stainless steel materials, which have the features of corrosion resistance, wear resistance, and easy replacement, ensuring the reliable use of different environmental protection equipment production lines.

Main products:

Chains used in decontamination and mud scraping in water treatment facilities: long pitch stainless steel conveying chain, sludge collector chain, sludge tank driving chain, etc.

Chains for recycling equipment: garbage disposal chains and other unique chains.

(2) Metallurgical Industry

Through continuous innovation, research, and development, various chains suitable for the metallurgical industry are manufactured, including chains for plate conveyors for conveying ore and waste, chains for producing metal cooling conveyors such as steel pipes and bars, chains for drawing steel products and various unique chains.

Features:

The metallurgical chain is highly reliable and suitable for high temperature, heavy load, continuous impact load, dust, iron filings and scales, corrosion and high humidity, etc. Personalized system solutions are provided according to user requirements.

Main products:

Steel coil conveying chain, steel pipe production line chain, and other steel mill giving chains; Cathode copper conveyor chain, etc.

(3) Food Industries

Chain for the food industry is widely used in various food processing machinery, such as meat production line, noodle making machinery, sugar making machinery, laver processing equipment, melon seeds processing equipment, sausage processing equipment, dairy filling equipment, ice cream production equipment, etc.

Features:

Different working conditions, optimized design, unique process, and high-quality alloy steel and stainless steel are adopted, which improves the chain’s corrosion resistance and wear resistance and meets the requirements of clean production and reliable use of various equipment.

● Chain for slaughter equipment: with high strength, good corrosion resistance, and wear resistance;

●Chain for flour making equipment: it has good anti-corrosion and wear resistance;

● Chain for fruit selection equipment: it has the characteristics of stable operation and high synchronization;

● Chain for sausage processing, ice cream production, dairy filling, and other equipment: it has the features of corrosion resistance and cleanliness;

● Chain for sugar machinery and palm oil production line: with high strength, good corrosion resistance, and wear resistance;

Main products:

Roller chain, long pitch conveying chain, stainless steel chain, unique chains with special surface treatment, etc.

(4) Health Medicine Industry

The chain used in the health medicine industry is applied to many production and service fields closely related to human health, such as pharmaceutical products, health products, nutritious foods, medical equipment, health appliances, leisure, and fitness.

Features:

Optimized design and reasonable material selection are adapted to meet corrosion resistance requirements, clean production, and reliable use of all kinds of equipment.

● The rubber glove chain has formed a series of products. Through unique design, it can meet the requirements of a longer, faster, high-quality, and efficient manufacturing of rubber glove production line.

Main products:

Mask production line chain: particular chain for mask machine;

Rubber glove production line chain: rubber glove conveying chain;

Chain for medical and health care equipment: stainless steel chain;

Chain for leisure and fitness machinery: particular chain for amusement facilities.

(5) Packaging Machinery Industry

Chains used in the packaging machinery industry are used in food packaging, pharmaceutical packaging, industrial/electronic product packaging, and other fields, mainly involving chains used in tinplate can making, film stretching, food packaging, and other packaging machinery and other equipment.

Features:

Chain for packaging machinery has good wear resistance, high synchronization, and good temperature resistance.

● Film stretching/clamping chain:</strong> it has the characteristics of cleanness, corrosion resistance, high precision, and long life.

Main products:

Chain for tin printing can making equipment: chain of tin printing drying room line;

Chain for film equipment: film stretching chain and film clamping chain;

Chain for packaging machinery: roller chain, long pitch conveyor chain, stainless steel chain.

(6) Logistics Transportation Industry

The chain used in the logistics transportation industry is used in the transportation, sorting, storage, sub-packaging, and other processes in the fields of express delivery, electronic industry, catering and food, etc., which mainly involves the chain used for package sorting, storage system, cold and hot transportation, and other equipment.

Features:

The product has wear resistance, stable running, and other performances and meets the use requirements of different working conditions such as poor lubrication conditions, high synchronization, fast running speed, and small side bending radius.

Main products:

Stainless steel chain, short pitch roller chain, double pitch roller chain, straight edge roller chain, etc.